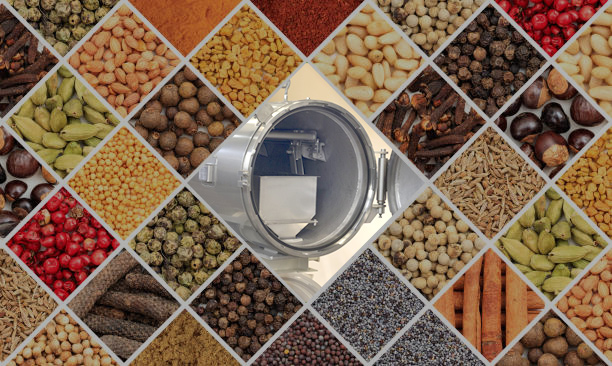

STEAM STERILIZATION

We have a Steam Sterilization facility to treat microbial contaminations in Spices & Herbs. Our unique Steam sterilization process treats products through Saturated Steam and ensures minimal damage to the organoleptic characteristics of the treated products.

Basic scope of supply steam sterilizing plant

- Sterilizer, complete with support frame, platform and staircase

- Wet scrubber/ Cleaning in Place unit for sterilizer

- Fluid bed dryer/cooler

- Sterile air supply unit for fluid bed dryer/cooler

- Dust separator for exhaust air from fluid bed dryer/cooler

- Central control panel (PLC and suitable for data acquisition for HACCP)

- Instrumentation

- Spare parts for the first year of operation

- Supervision of erection and commissioning plus training of operators

- Pneumatic product feed to sterilizer using sterile air from filter unit

- Pneumatic product discharge from fluid bed dryer/cooler to packing room using sterile air from filter unit

- Finisher to turn agglomerates back into a free flowing powder

| TPC | Less Than 10,000 |

| E.Coli | Negative. |

| Salmonella | Negative. |

| Coli forms | Less Than 50 CFU/gram. |

| Yeast and Moulds | Less Than 100 CFU/gram. |

| Enterobacteriaceae | Less Than 10 CFU/gram. |

| Bacillus cereus | Less Than 100 CFU/gram. |

| Clostridium Perringers | Less Than 10 CFU/gram. |

| Staphylococcus aureus | Less Than 100 CFU/gram |